Das Lithium-Problem

- Lithium-Herstellprozesse sind überwiegend umwelt- und klimaschädlich.

- Lithium-Produktion ist ressourcen- und energieintensiv.

- Lithium muss zu über 95% nach Europa importiert werden.

Wir ändern das.

Lithium made by Prime Lithium

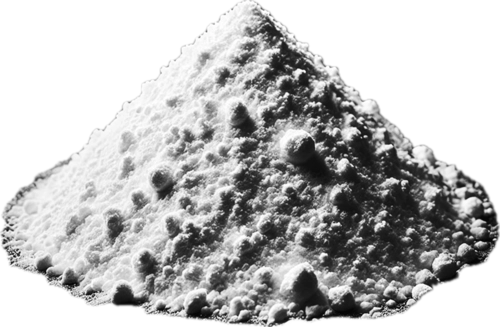

Der Schlüsselrohstoff für High-Performance-Batterien

Zum Patent angemeldete High-Tech-Herstellung von Lithiumhydroxid

Revolutionärer Qualitätslevel

Keine CO2-Emissionen (Scope 1)

Integriertes Lithium-Recycling

Produktionsbeginn 2031

Für 500.000 Elektrofahrzeuge pro Jahr

Made in Europe

Denn: Nur mit hochreinem, nachhaltig produziertem Lithiumhydroxid können die Batterien der Zukunft Wirklichkeit werden.

Unser Produktionsstandort: Stade bei Hamburg

Die Revolution in der Lithiumproduktion

Management

Das Management von Prime Lithium vereint jahrzehntelange Erfahrung in der Chemieindustrie. Unter dem Vorsitz von Dr. Axel C. Heitmann, langjähriger CEO der LANXESS AG, treibt der Vorstand die nachhaltige Lithiumproduktion in Europa mit strategischem Weitblick und technologischer Exzellenz voran.

Vorstand Dr. Walter Bürger-Kley bringt über 30 Jahre Beratungserfahrung in der nationalen und internationalen Chemieindustrie ein-zuletzt mit seiner eigenen Strategieberatung Stratley und als Partner bei KPMG.

Gestalten Sie mit uns die Batterieindustrie von morgen.

Prime Lithium steht für Innovation, nachhaltiges Wachstum und eine sichere europäische Lithiumversorgung.

Mit der ersten nicht-kommerziellen Produktionsanlage erreichen wir bald unseren nächsten Meilenstein auf dem Weg zur industriellen Produktion. Unsere Technologie ist marktreif, die Strategie klar – und der Zeitpunkt ideal, um frühzeitig an der Wertentwicklung eines zukunftsweisenden Unternehmens teilzuhaben. Wir laden ausgewählte Investoren ein, diesen Weg mit uns zu gehen.

Bei Interesse senden wir Ihnen gerne unseren Investoren-Teaser.

Investoren-Teaser anfordernTonnen Lithium ab 2031

E-Autos pro Jahr durch unser Lithium

CO2-Emissionen

(Scope 1)

CAGR im

Lithiummarkt

Werde Teil unseres Teams!

Du willst die Zukunft der Lithiumwelt mitgestalten und an einer Schlüsseltechnologie für die Energiewende arbeiten? Dann werde Teil von Prime Lithium – und bring deine Ideen in ein innovatives Umfeld ein.

Entdecke jetzt unsere aktuellen Stellenangebote und baue mit uns die Lithiumproduktion von morgen!

Jetzt bewerben